Shipbuilding and shiprepair equipment

Ship transfer systems (STS) are designed for longitudinal and transversal transportation of block sections, vessels and submarines on the territory of the shipyard during ship construction and repair.

TEHNOROS is a leading Russian developer and manufacturer of modern ship transfer systems with automated control. TEHNOROS ship transfer systems meet or exceed the best European models in quality and functionality.

The equipment is produced in accordance with Technical Conditions.

All the equipment is designed and manufactured within TEHNOROS own production site on the territory of the Russian Federation.

The production has the complete facility of test-bench equipment required for carrying out the trial run of all STS-hydraulic system hydraulic components and ready-assembled hydraulic pump units, as well as for static tests of ready-assembled slipway trolleys.

The standard modular STS for ship/submarines transporting consists of:

1. Self-propelled slipway trolleys (as well as the use of rotatable trolleys is available).

2. Autonomous self-propelled hydraulic aggregate (hydraulic pump unit with automated control) with electric or diesel engine of driving hydraulic units.

3. Trolley for high-pressure hoses.

4. Set of trolley connections.

5. Set of high-pressure hoses.

6. Keel beams (option).

7. Load-bearing longitudinal beams (option).

8. Cross-beam rigid links (option),

9. Hydraulic centering devices (option).

An example of a standard STS with loading capacity 14 000 tons is presented below:

The total loading capacity of the STS generally depends on:

- loading capacity and the number of the slipway trolleys included;

- capacity and number of hydraulic pump units feeding STS.

At the moment, we are ready to design and supply to the customer an STS with a loading capacity up to 50 000 tons.

Ship-carrying slipway trolleys are available in both submersible and non-submersible versions. The use of submersible trolleys is possible in both fresh and seawater.

The number of the slipway trolleys in the system is determined by calculation and depends on the next technical characteristics: weight and size of representative vessels (running load from vessels/submarines) intended for transportation by the STS. The arrangement of trolleys under the transported objects is related to a number of factors: the weight plot and strong places of the ship’s hull, the size of the transported object, the track of the slipway lines as well as the design of the descent device.

When it necessary to carry out both longitudinal and transversal movement on the slipway field, the STS is being equipped with rotatable trolleys.

The main advantages of modern STS with rotatable trolleys:

- easy movement of the STS both along and across the ship's keel, without intermediate transfers, which is achieved by using rotating (on 90 degrees) trolleys;

- no need to use an additional transborder with the transborder pit, it allows more efficiently to use the total area of the shipyard. A slipway field with a set of rails used for ships moving can be also available for moving personnel and vehicles;

- autonomy (a ship train may include a diesel unit which can give the power for electrical and hydraulic units);

- high degree of automation;

- high degree of flexibility;

- low operating costs;

- less number of operating personnel;

- synchronous and controlled lifting of the vessel on the hydraulic cylinders and, as a result, a lower probability of deformation of the vessel's hull

- high reliability

When using STS for large-scale ship assembly, the slipway trolleys (both standard and rotatable) are equipped with hydraulic centering devices. It allows to move the block sections in all directions.

The hydraulic system of the main STS actuators consists of six independently controlled contours:

- four contours of vertical movement of the transported ship or block (contours of hydraulic jack zones);

- two contours of horizontal movement of the transported ship or block (contours of lines of the hydraulic move)

The hydraulic system of vertical displacement contours allows to move up and down the vessel, as well as to create, eliminate it’s roll and trim.

The hydraulic system of vertical displacement contours allows combining any two contours into one, thereby achieving three-zone support of the vessel with uniform load on each zone of hydraulic jacks, regardless of the curvature of the rail track.

The hydraulic system of horizontal displacement contours allows moving the ship around the yard, as well as creating and eliminating the distortion of two trolley lines relatively to each other when placing the trolleys under the cross beams.

The control of main STS executive mechanisms as well as the auxiliary equipment is automated-electrohydraulic. The STS control is carried out by the control panel located in the hydro hydraulic pump unit.

Optionally it is possible to design, manufacture and supply the STS with an electric trolley drive.

TEHNOROS is a leading Russian developer and manufacturer of modern ship transfer systems with automated control. TEHNOROS ship transfer systems meet or exceed the best European models in quality and functionality.

The equipment is produced in accordance with Technical Conditions.

All the equipment is designed and manufactured within TEHNOROS own production site on the territory of the Russian Federation.

The production has the complete facility of test-bench equipment required for carrying out the trial run of all STS-hydraulic system hydraulic components and ready-assembled hydraulic pump units, as well as for static tests of ready-assembled slipway trolleys.

The standard modular STS for ship/submarines transporting consists of:

1. Self-propelled slipway trolleys (as well as the use of rotatable trolleys is available).

2. Autonomous self-propelled hydraulic aggregate (hydraulic pump unit with automated control) with electric or diesel engine of driving hydraulic units.

3. Trolley for high-pressure hoses.

4. Set of trolley connections.

5. Set of high-pressure hoses.

6. Keel beams (option).

7. Load-bearing longitudinal beams (option).

8. Cross-beam rigid links (option),

9. Hydraulic centering devices (option).

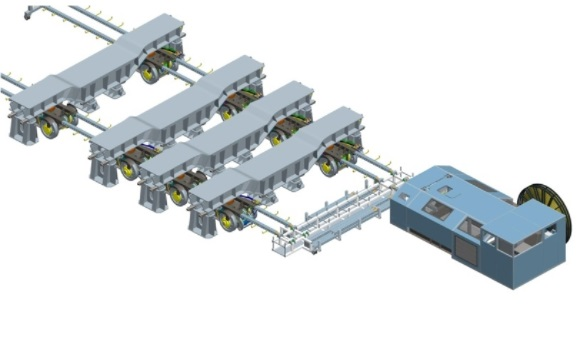

An example of a standard STS with loading capacity 14 000 tons is presented below:

3D-model of ship transfer system with loading capacity 14 000 tons

The total loading capacity of the STS generally depends on:

- loading capacity and the number of the slipway trolleys included;

- capacity and number of hydraulic pump units feeding STS.

At the moment, we are ready to design and supply to the customer an STS with a loading capacity up to 50 000 tons.

Ship-carrying slipway trolleys are available in both submersible and non-submersible versions. The use of submersible trolleys is possible in both fresh and seawater.

The number of the slipway trolleys in the system is determined by calculation and depends on the next technical characteristics: weight and size of representative vessels (running load from vessels/submarines) intended for transportation by the STS. The arrangement of trolleys under the transported objects is related to a number of factors: the weight plot and strong places of the ship’s hull, the size of the transported object, the track of the slipway lines as well as the design of the descent device.

When it necessary to carry out both longitudinal and transversal movement on the slipway field, the STS is being equipped with rotatable trolleys.

The main advantages of modern STS with rotatable trolleys:

- easy movement of the STS both along and across the ship's keel, without intermediate transfers, which is achieved by using rotating (on 90 degrees) trolleys;

- no need to use an additional transborder with the transborder pit, it allows more efficiently to use the total area of the shipyard. A slipway field with a set of rails used for ships moving can be also available for moving personnel and vehicles;

- autonomy (a ship train may include a diesel unit which can give the power for electrical and hydraulic units);

- high degree of automation;

- high degree of flexibility;

- low operating costs;

- less number of operating personnel;

- synchronous and controlled lifting of the vessel on the hydraulic cylinders and, as a result, a lower probability of deformation of the vessel's hull

- high reliability

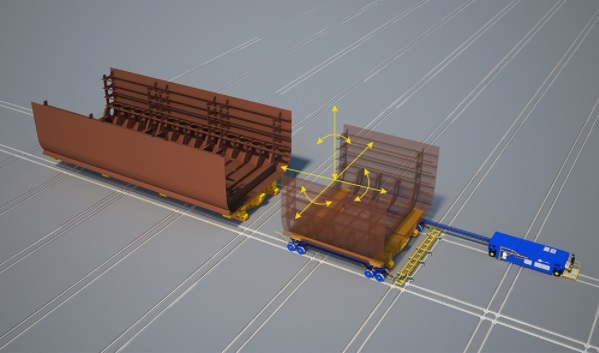

When using STS for large-scale ship assembly, the slipway trolleys (both standard and rotatable) are equipped with hydraulic centering devices. It allows to move the block sections in all directions.

Using STS for large-scale ship assembly. Positioning the unit on 6 axes

The hydraulic system of the main STS actuators consists of six independently controlled contours:

- four contours of vertical movement of the transported ship or block (contours of hydraulic jack zones);

- two contours of horizontal movement of the transported ship or block (contours of lines of the hydraulic move)

The hydraulic system of vertical displacement contours allows to move up and down the vessel, as well as to create, eliminate it’s roll and trim.

The hydraulic system of vertical displacement contours allows combining any two contours into one, thereby achieving three-zone support of the vessel with uniform load on each zone of hydraulic jacks, regardless of the curvature of the rail track.

The hydraulic system of horizontal displacement contours allows moving the ship around the yard, as well as creating and eliminating the distortion of two trolley lines relatively to each other when placing the trolleys under the cross beams.

The control of main STS executive mechanisms as well as the auxiliary equipment is automated-electrohydraulic. The STS control is carried out by the control panel located in the hydro hydraulic pump unit.

Optionally it is possible to design, manufacture and supply the STS with an electric trolley drive.

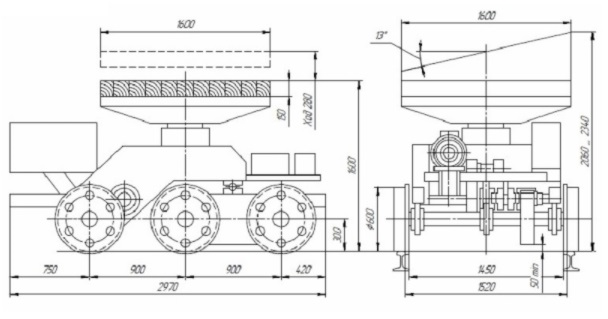

Overall drawing of the electric driven slipway trolley with lifting capacity 125 t