Vertical shiplifts

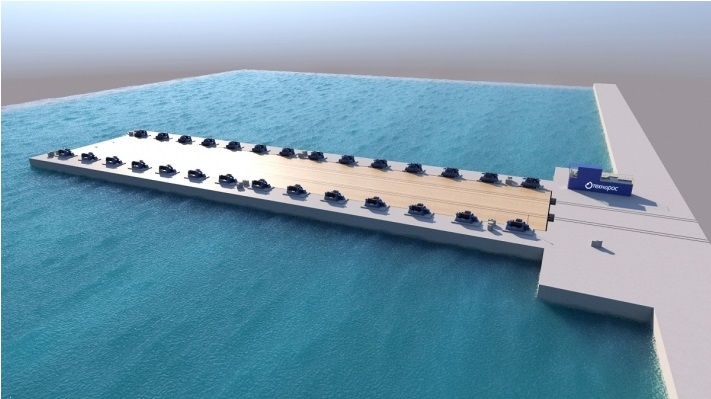

Vertical shiplift is a vertical type of ship lifting/launching device. This equipment is intended for controlled automated launching and lifting of ships and submarines.

Shiplifts are manufactured in accordance with Technical Conditions 6418-005-58311503-2016.

TEHNOROS offers design, production and supply of vertical shiplifts with a working lifting capacity of up to 30 000 tons.

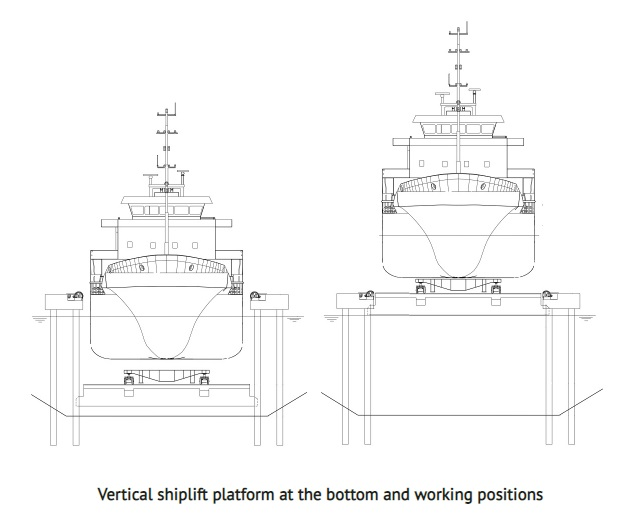

A vertical ship lift is a horizontal platform for launching vessels from the slipway level to the water or lifting a vessel out of the water. Vertical movement of the platform is carried out by using a system of synchronized winches.

1. Smaller plan dimensions compared to self-loading dock chambers and slips.

2. Less construction and installation work and time needed for construction.

3. Speed and high controllability of lifting and lowering operations.

4. Independence of lifting operations from fluctuations of the sea.

5. Low operating costs (high reliability and lack of underwater serviced mechanisms).

6. Less possibility to deform the bottom of the vessel (submarine) due to the use of a rigid support platform.

The main components of the vertical shiplift are:

1. Automated control system.

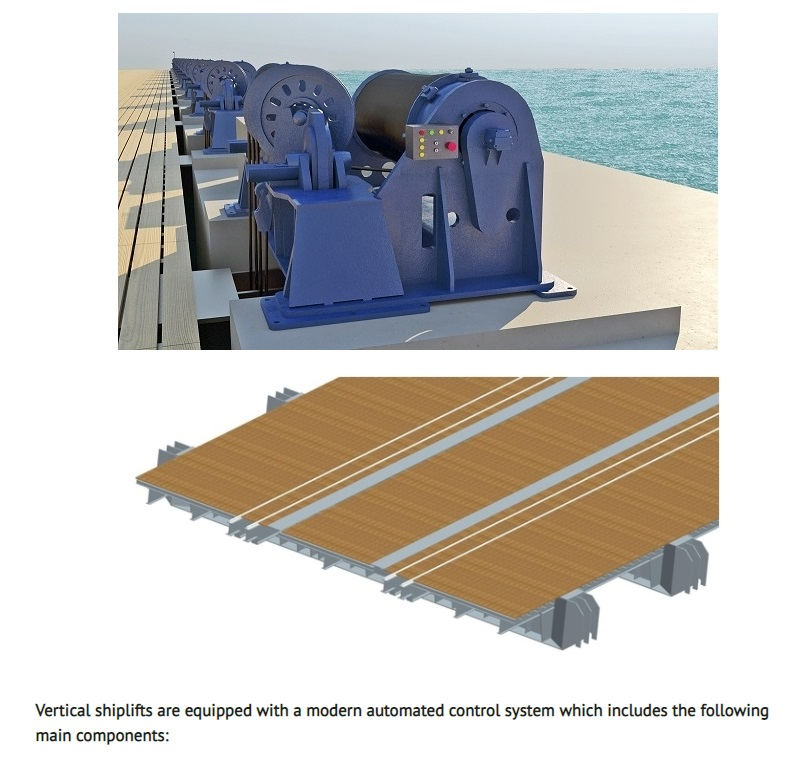

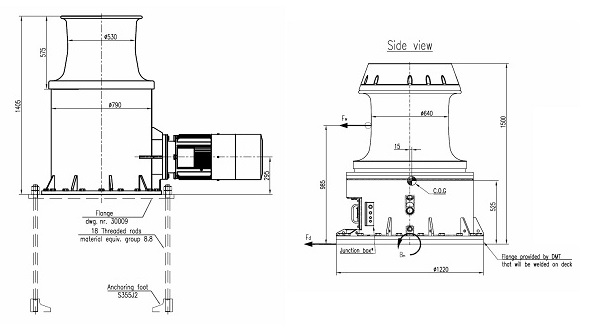

2. Assembled hoist winches (with the platform fixing nodes).

3. Vertical pillars.

4. Lifting platform.

2. Control cabin (CC).

3. Local winch control stations.

4. Technological TV system.

5. System of objective control.

The automated control system provides the following basic operations:

1. Platform movement management:

- moving upward;

- moving downward;

- lifting up to one of the specified levels (0m, service);

- lowering down to one of the specified levels (0m, -12 m);

- heaving up from -12 m level up to the touch of the vessel (when the specified load occurs);

- heaving down from the 0m level down to the vessel's descent (load reduction by a set amount);

- stop;

- fixing at one of the specified levels (0m, service);

- setting up (service mode).

2. Weighing vessels and determining the coordinates of the projection of the center of gravity on the platform plane.

3. Smooth increase and decrease of platform speed with acceleration set by the operator.

4. Automatic maintaining of the platform's angular position set by the operator (set values of list and trim).

5. Automatic and manual alignment (roll and trim equalization) of the platform.

6. Adjusting the speed of the platform movement within 20-100% of the rated speed.

7. Constant automatic monitoring of the speed and position of the platform.

8. Setting-up mode (Service mode) with independent control of each winch.

9. Platform braking control in case of power failure.

10. Ongoing and pre-start diagnostics of the state of electric drives.

11. Pre-start, starting, operating, emergency light and sound alarms.

The automated control system is powered by a three-phase alternating current with a voltage of 380V and a frequency of 50 Hz. The power supply voltage is applied to the electrical equipment cabin (EEC) on the main automatic switch of the input device panel. Then, through the contacts of the main contactor, power is supplied to the power part of the electrical equipment.

The basic technical offer uses one cabin of electrical equipment. At the request of the Customer, to optimize the length of cable lines, it is possible to use two EECs (agreed at the stage of the technical project), located one on each side of the hydraulic structure of the ship lift.

Options:

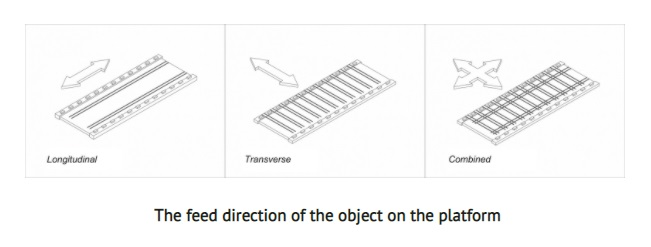

Basic input/output and positioning system of the vessel consists of electric saws, deflecting blocks and bale bars with rolls. This equipment is installed on reinforced concrete abutments of a vertical shiplift. The type of spires and their installation locations must be approved by the hydrotechnical part designer.

The scheme for entering ships (without specifying tugs) is shown below.

An automated ship input/output and positioning system can be delivered on request.

Conditions for safe lifting/launching (docking) of the vessel.

To ensure the most safe lifting/launching of the vessel, complete with a vertical shiplift it is necessary to use slipway trolleys and keel beams from the STS supplied with the shiplift, or similar equipment agreed by the Supplier for joint work with the shiplift.

The maximum lifting capacity of the shiplift is provided with a uniform load on all winches.

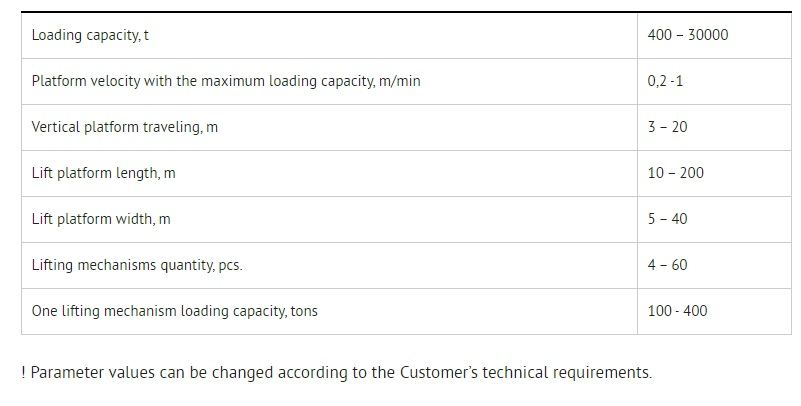

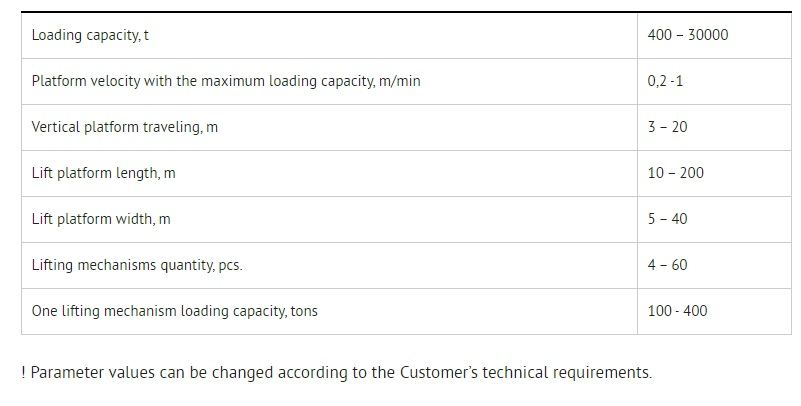

Main design specifications of the vertical shiplift

Shiplifts are manufactured in accordance with Technical Conditions 6418-005-58311503-2016.

TEHNOROS offers design, production and supply of vertical shiplifts with a working lifting capacity of up to 30 000 tons.

A vertical ship lift is a horizontal platform for launching vessels from the slipway level to the water or lifting a vessel out of the water. Vertical movement of the platform is carried out by using a system of synchronized winches.

1. Smaller plan dimensions compared to self-loading dock chambers and slips.

2. Less construction and installation work and time needed for construction.

3. Speed and high controllability of lifting and lowering operations.

4. Independence of lifting operations from fluctuations of the sea.

5. Low operating costs (high reliability and lack of underwater serviced mechanisms).

6. Less possibility to deform the bottom of the vessel (submarine) due to the use of a rigid support platform.

The main components of the vertical shiplift are:

1. Automated control system.

2. Assembled hoist winches (with the platform fixing nodes).

3. Vertical pillars.

4. Lifting platform.

2. Control cabin (CC).

3. Local winch control stations.

4. Technological TV system.

5. System of objective control.

Automated control system

The automated control system provides the following basic operations:

1. Platform movement management:

- moving upward;

- moving downward;

- lifting up to one of the specified levels (0m, service);

- lowering down to one of the specified levels (0m, -12 m);

- heaving up from -12 m level up to the touch of the vessel (when the specified load occurs);

- heaving down from the 0m level down to the vessel's descent (load reduction by a set amount);

- stop;

- fixing at one of the specified levels (0m, service);

- setting up (service mode).

2. Weighing vessels and determining the coordinates of the projection of the center of gravity on the platform plane.

3. Smooth increase and decrease of platform speed with acceleration set by the operator.

4. Automatic maintaining of the platform's angular position set by the operator (set values of list and trim).

5. Automatic and manual alignment (roll and trim equalization) of the platform.

6. Adjusting the speed of the platform movement within 20-100% of the rated speed.

7. Constant automatic monitoring of the speed and position of the platform.

8. Setting-up mode (Service mode) with independent control of each winch.

9. Platform braking control in case of power failure.

10. Ongoing and pre-start diagnostics of the state of electric drives.

11. Pre-start, starting, operating, emergency light and sound alarms.

Vertical shiplift control desk

The automated control system is powered by a three-phase alternating current with a voltage of 380V and a frequency of 50 Hz. The power supply voltage is applied to the electrical equipment cabin (EEC) on the main automatic switch of the input device panel. Then, through the contacts of the main contactor, power is supplied to the power part of the electrical equipment.

The basic technical offer uses one cabin of electrical equipment. At the request of the Customer, to optimize the length of cable lines, it is possible to use two EECs (agreed at the stage of the technical project), located one on each side of the hydraulic structure of the ship lift.

Options:

Basic input/output and positioning system of the vessel consists of electric saws, deflecting blocks and bale bars with rolls. This equipment is installed on reinforced concrete abutments of a vertical shiplift. The type of spires and their installation locations must be approved by the hydrotechnical part designer.

Vertical shiplift input/output system

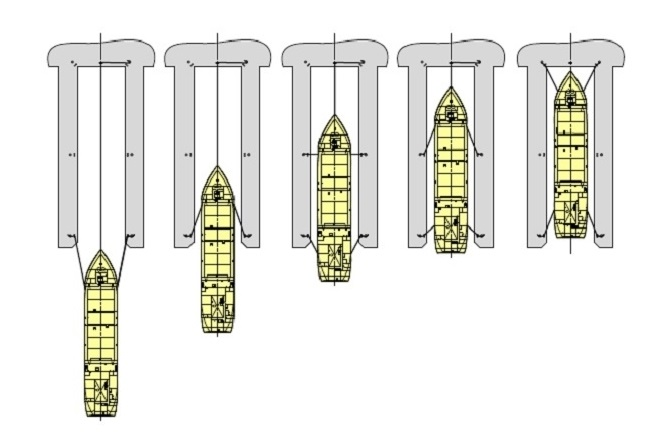

The scheme for entering ships (without specifying tugs) is shown below.

The scheme for entering ships

An automated ship input/output and positioning system can be delivered on request.

Conditions for safe lifting/launching (docking) of the vessel.

To ensure the most safe lifting/launching of the vessel, complete with a vertical shiplift it is necessary to use slipway trolleys and keel beams from the STS supplied with the shiplift, or similar equipment agreed by the Supplier for joint work with the shiplift.

The maximum lifting capacity of the shiplift is provided with a uniform load on all winches.

Main design specifications of the vertical shiplift