History

"TEHNOROS" Production Association ("TEHNOROS") was founded in 1991 and in its early years specialized in the supply of various materials handling equipment to large domestic enterprises.

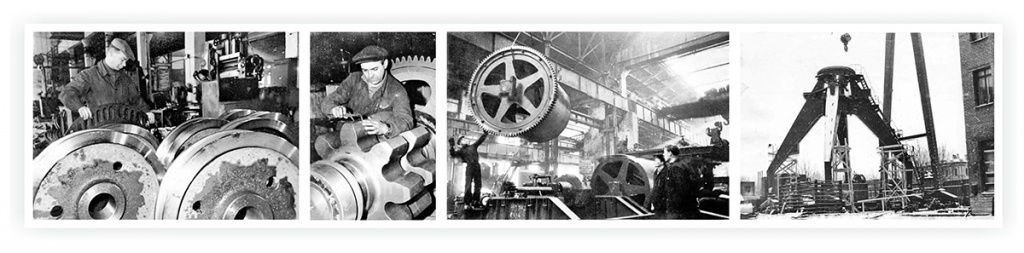

In 2003, "TEHNOROS" affiliated "Podyemtransmash", OJSC. The plant became the main production site of "TEHNOROS". The majority of "Podyemtransmash" employees and the archive of engineering drawings and technological documentation were transferred to the new enterprise, machines and other equipment of the machine shop were transported as well. Since that time, "TEHNOROS" has expanded its specialization and started to design and manufacture materials handling equipment itself.

"Podyemtransmash", was the founder of the Leningrad design school and one of the leading manufacturers of materials handling equipment in the USSR.

Production history of the company since 1868:

1868

The origin of the enterprise. In 1868, the Main workshops of the Department of North-Western Railways (Petersburg – Warsaw railway) of the Ministry of Railways were opened to repair rolling stock. The workshops produced six passenger and freight locomotives.

1930

The St. Petersburg repair shops at the Warsaw railway were reorganized into the Leningrad state plant of lifting and transport structures and re-purposed for the production of various types of crane equipment.

1938

The plant produced the first 112 gearboxes, produced 35 peat harvesting machines, and 18 tower cranes.

1941

With the beginning of The Great Patriotic War the equipment was evacuated. The plant started repairing tanks and producing various types of weapons.

1956

The production of portal cranes with a load capacity from 3 to 30 tons was resumed. In the 50s, the plant was closely associated with research institutes and higher education institutions. Professors and candidates of science of the Polytechnic Institute actively participated in the development and design of new structures of materials handling equipment, developed new types of cranes: bridge, metallurgical, portal.

1957

Deliveries of lifting equipment for export were started. The plant came under the control of Ministry of heavy engineering.

1958

Mechanisms of unique double-cantilever cranes for the Bratskaya hydroelectric powerplant were manufactured.

1965

The upper structure for a 250-ton crane for installing oil rigs in the Caspian sea was manufactured.

A cable crane with a span of 1100 meters was manufactured for the construction of the Krasnoyarsk hydroelectric powerplant. The height of its supports is more than 100 meters.

1967

Two unique winches for the Sayano-Shushenskaya hydroelectric powerplant were manufactured.

1980

The 10 000th crane was released!

1982

84 portal cranes of various modifications, 56 special bridge cranes, 3 metallurgical and 3 semi-gantry cranes were manufactured. 8 unique cranes with a rotating trolley were manufactured for Nigeria. By order of the Ministry of heavy and transport engineering dated April 14, 1982, the Production Association "Lenpodyemtransmash" was established on the plant’s basis.

1993

On October 12, 1993, "Hoisting-and-transport mechanical engineering", OJSC (abbreviated in Russian "Podyemtransmash") was registered.

The 2000s

- in 2003, the company became a part of the “TEHNOROS” Production Association;

- production and delivery of portal handling and installation cranes of the Kirovets type continued to sea and river ports, as well as to service the storage bases of oil and gas producing and mining companies.

During the same period, the range of products was significantly expanded due to the production of special gantry and bridge cranes for “CHMK”, “NLMK”, “MMC “Norilsk Nickel”, “Apatit”, “RUSAL”, “Volga”, “Sinar” and “Seversk” pipe plants and other customers.

2008-2009

Rail-mounted gantry container reloaders (RMG type) were developed, manufactured and delivered for “TransContainer”. In the following years, “TEHNOROS” delivered 16 cranes of this type with a capacity of 36-45 tons under the spreader for various sites of “TransContainer”.

2011

In 2011, “TEHNOROS” supplied:

- bridge crane with lifting capacity of 200/30 t to “Sokolovsko-sarbayskoe GPO”, JSC;

- bridge grab crane with lifting capacity of 20 t with a span of 42 m of heavy duty operation for “LUKOIL”;

- several special cranes (including those with controlled claws with lifting capacity of 150/110 t) for “NLMK” and cranes with lifting capacity of 25/15/15 t with a rotating trolley for “NLMK-Kaluga”;

- transformer crane (with different geometric parameters and lifting capacity at different stages of operation) for “SSC NIIAR”, JSC/

2012

This year was a landmark for the company and a breakthrough in terms of working with the country's metallurgical enterprises, as the supply and commissioning of a scrapyard machine with a lifting capacity of 130+130 t for a major Russian steel mill and a four-beam bridge pouring crane with a lifting capacity of 150+80/20 t for “NLMK” were completed.

In the same year, a large batch of magnetic grab cranes was delivered to “Kaluga research and production electrometallurgical plant” and a bridge crane with a lifting capacity of 200/50 t was delivered to “Petrozavodskmash”.

Also in 2012, a separate Department was created for the development and production of bulk materials handling equipment, which designed and supplied the portal ship loading machine "Pechora" with telescopic boom to Sakhalin island.

2013

- the development of a non-customized range of portal reloading and mounting cranes of “Voskhod” type (with a straight-firing system and a flexible drawbar) and "Zubr" type (with an articulated boom and a rigid drawbar) was accomplished;

- a new-generation “Voskhod” type gantry reloading crane with a lifting capacity of 8 t (in a grab mode at a 30-meter reach) was supplied to the Angarsk petrochemical company;

- the company has supplied 10 special bridge cranes with a lifting capacity of from 20 to 40 tons for the new shop of “Chelyabinsk pipe rolling plant”;

- a heavy plate feeder was supplied to “Tagmet”, JSC.

2014

Several significant projects were carried out in 2014:

- accomplishment of the unique, in terms of the implemented production model, supply of 6 cranes of various lifting capacities for the Vostochny cosmodrome;

- supply to one of a national customer of a new generation portal reloading crane of “Zubr” brand with a lifting capacity of 63 t and with a 40 m boom reach, designed for handling containers, bulk cargo and general cargoes;

- supply of 2 heavy mode special bridge grab cranes with a lifting capacity of 32 t, with a span of 40 m to "LUKOIL-Permnefteorgsintez" and of 3 heavy mode special bridge grab cranes with a lifting capacity of 20 t, with a span of 34 m to "MMC "Norilsk Nickel", JSC;

- the Department for the development and manufacture of shipbuilding and ship repair equipment was established. The department's task was to meet the demand for ship transfer and lifting equipment for shipyards and ship repair plants.

2015-2016

- the first domestic coordinate ship loading machine "Neva-1500" was designed, supplied, installed and put into operation at the Murmansk bulk terminal (“MHC “EuroChem”, JSC);

- a metallurgical crane with a lifting capacity of 120+32/10 t was put into operation at the “Belarusian metallurgical plant”;

- in 2016, the ship loading machine “Pechora” was modernized with an increase in capacity to 2300 t/h for coal handling;

- supply, installation, commissioning and start-up of several portal cranes "Kirovets" with a lifting capacity of 32 t to "Norilsk Nickel" and of portal cranes "Zubr" with a lifting capacity of from 32 to 80 t to the port of Peledui and the port of Vung Tau (Vietnam) were carried out. The supply of equipment to Vietnam was awarded at the "Exporter of the year" competition in 2017;

- the transfer bridge at “DVZ “Zvezda”, JSC was modernized with an increase in capacity to 14 000 t;

- a patent for a self-propelled rotating ship handling trolley for the ship transfer system was received.

During this period, we completed our own innovative development - the Remote monitoring system for cranes. The system allows you to record remotely the parameters and performance of cranes, analyze the efficiency of the work performed by the crane, energy consumption, as well as monitor the resource of mechanisms and the crane as a whole.

One of the system variants was supplied and put into commercial operation at “TransContainer” as a Dispatching system for gantry container cranes. The system collects and analyzes detailed information about the operation of cranes located at the company's container terminals in various regions of the Russian Federation and provides analysis of cargo flow processing, work efficiency, and allows to make investment decisions.

2017

- the Department of bulk materials handling equipment has developed a rotary ship loading machine for grain cargoes;

- a portal loading crane "Zubr" with a lifting capacity of 32 t, designed for transshipment of bulk and general cargoes, was supplied, installed and put into operation in the port of Dudinka.

2018

2018 was a special year for Production Association “TEHNOROS”, as there contracts were signed for:

- design of a unique gantry type chain bucket reclaimer with a capacity of 1200 t/h for a metallurgical plant in the Czech Republic:

- supply of the first Russian ship transfer system with automated control system with a lifting capacity of 14 000 t, including 42 drive and 42 non-drive trolleys, as well as 2 hydraulic pump units;

- supply of a bridge four-block casting crane with a lifting capacity of 210+63/ 20 t for one of Russia's major steel mills.

In the same year, the following equipment was put into service:

- special gantry crane with a lifting capacity of 560 t for servicing the gates of the Shamaldysay hydroelectric powerplant (Kyrgyzstan);

- metallurgical bridge crane with a lifting capacity of 150 t at “NLMK”;

- bridge special cranes with a lifting capacity of from 20 to 160 t at “EuroChem-Usolsky potash plant”.

2019

- the ship transfer system with a lifting capacity of 14 000 t was put into operation;

- 2 special cranes with a rotating trolley with a lifting capacity of 45/45/45 t were supplied to one of Russia's major steel mills;

- a gantry crane with a lifting capacity of 50 t (in the version for cold climates) was put into operation at the “Bystrinsky GOK”;

- a special gantry crane with a lifting capacity of 32 tons, designed to move a container with fish from the lower to the upper reaches of the Krasnodar Reservoir, was put into service;

- Production Association “TEHNOROS” became a dealer of THIELE (Germany) and started selling chains and sprockets for reclaimers, conveyors and elevators in Russia.

In 2019, “Production Association “Tehnoros”, CJSC was renamed to “Production Association “Podyemtransmash”, JSC (abbreviated as “PA “Podyemtransmash”, JSC). Thus, the firm was returned to the historical name of the enterprise, the successor of which it became in 2003. At the same time, the company continued its activities in the market under the brand Production Association "TEHNOROS".

2020

- work on supervision and commissioning of a chain reclaimer with a capacity of 1200 t/h in the Czech Republic continues;

- a contract for the supply of a special bridge crane with pickups with a lifting capacity of 62/35/20 t, intended for rail transportation, was signed with one of Russia's major steel mills;

- a contract for the supply of a bridge metallurgical four-block casting crane with a lifting capacity of 210+63/20 t was signed with “Ural Steel”, JSC.