Design and manufacturing of metallurgical overhead (bridge) cranes

Main features of metallurgical overhead (bridge) cranes:

- Heavy and very heavy mode of operation (A5-A8);

- Protection from exposure of extremely aggressive environments;

- The increased level of reliability and safety;

- The increased thermal protection of cabin and equipment;

- Smooth travelling over the entire range of loads;

- Ingress protection rating of electrical room and equipment not less than IP54;

- Appliance of heat resistant protecting sleeves for cable laying;

- The increased maintainability, quick unit replacements;

- Possibility of long-term work after one motor failure before its replacement;

- No limits of working motions combination;

- The increased safety margins of components and ropes;

- Automated collection and display of information about equipment condition and actual parameters of the crane.

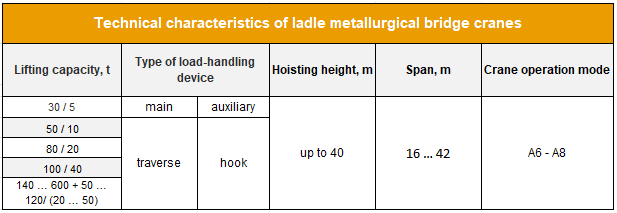

Ladle overhead crane

Ladle overhead (bridge) cranes are the main handling equipment, which is used at metallurgical enterprises for hot metal transportation, charging and casting.

Generally, they are applied for charging molten cast iron into converters or into charging aisle of electric furnace, as well as for transporting a ladle with molten steel onto a receiving device or transporting molten steel onto a ladle furnace for further metal purification.

Ladle overhead (bridge) cranes are intended for maintenance of converter and steel shops of metallurgical enterprises. They are designed for heavy and very heavy modes of operation that include high, connected with manufacturing technique, dead-weight, dynamic and shock loads.

Ladle metallurgical overhead (bridge) cranes are divided into transporting, charging and casting cranes.

The transporting metallurgical foundry bridge crane

The transporting, etallurgical overhead crane is intended for transferring a ladle with molten metal from a casting-ladle transfer car onto a turret of a continuous casting machine or a ladle furnace.

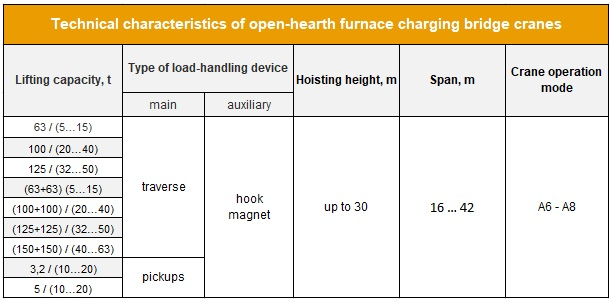

Open-hearth furnace charging crane

Metallurgical open-hearth furnace charging bridge cranes are intended for transporting and dumping a mould with burden or feedings into open-hearth furnaces and basic oxygen furnaces of steel shops of metallurgical enterprises, as well as for transfer operations during furnaces repair and maintenance.

Depending on mould design, the main trolley has essentially different structures: for moulds, which are a scoop and which are unloaded through an open end, they apply trolleys with a lifting mechanism, consisting of two winches with four suspensions or with four-hook traverse which provide a scoop incline during its unloading – scrap charging into a furnace.

In this case the crane has the second name – scrap charging cranes. They are intended for operations with large scoops for scrap loading into basic oxygen furnaces. Their lifting capacity, as a rule, is more than 100 tones.

To produce an open-hearth furnace charging crane, we use cutting-edge components of leading manufactures and reliable suppliers, including the Customer’s wishes and recommendations.

Charging crane

The charging overhead crane is actively used in the melting shops of metallurgical plants, as well as enterprises for the copper production.

Its functions include: loading scrap, defective anodes, cathodes, and cutting copper sheets. Similar equipment is also used for opening feeding holes and installing charging launders.

The main load-handling device of crane is the arm, which makes the capture of the muld and put it into rotation.

Today, such a complex produced by PA «TEHNOROS» is successfully used at large Russian metallurgical plants.

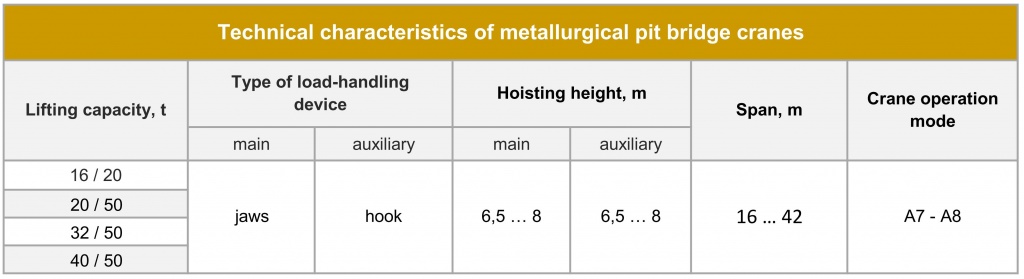

Metallurgical pit bridge crane

The metallurgical pit dogging bridge cranes are intended for operations in heating furnaces cells for ingots setting onto furnaces bottom, as well as for transportation of ingots, heated up to rolling temperature, to an ingot bogie or to a receiving roller table of a rolling mill.

Considering the specifics of operation, the metallurgical pit crane is designed for an operating temperature up to +80 degrees C and can stand short-term exposure of high temperatures from the furnace and the bars. The load-handling device of the metallurgical dogging crane is special jaws which can spin.

Except ingots operations, the pit cranes perform various auxiliary handling operations. For this purpose the jaws are equipped with hooks for cargo operations. The jaws are used for furnace bottom cleaning.

Metallurgical forge bridge crane

The forge crane consists of main and auxiliary trolleys, which moves on main and auxiliary bridges, connected by articulated hitches. The forge turner is fixed to the hook of the main trolley.

The forge cranes can travel a work piece by various methods: with a holder, without holder or in mount. As a rule, the holder is used during short work pieces treatment.

Because during forging the forge crane inevitably takes technological forces from the press or the hammer, during its designing we focus on reduction of dynamic overloads.

The forge crane lifting capacity is characterized by the sum of weights of a work piece and devices for work piece gripping.

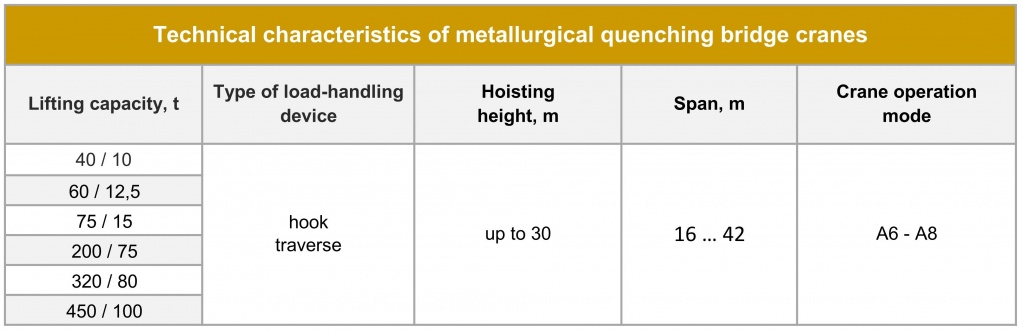

Metallurgical quenching bridge crane

The quenching metallurgical bridge cranes are applied in heat-treatment shops of machinery works. They are intended for handling operations, which are necessary in quenching process.

The metallurgical quenching crane consists of a bridge of standard framed construction (main longitudinal beams with end beams) and mechanisms, which have the increased speeds as compared with cranes for general purposes and, accordingly, higher installed power of electric motors.

The high speeds load transfer are necessary for minimization of work piece heating temperature loss in order to provide a work piece structure homogeneity in volume. The high speeds are very important parameters of quenching cranes.

In the table you can find technical characteristics of the basic range of bridge metallurgical quenching cranes with lifting capacity from 40/10 tones to 450/150 tones. According to your wish, these parameters can be changed.

It would be a pleasure for us to offer the most efficient solution to your business. Just call us +7 (911) 975-48-91

Our specialists will answer all your questions and give you detailed information about our equipment. You can write us at info@tehnoros.ru, as well.

Back to the list