Wagon tipplers. Design and manufacturing.

Steel mills, coke-chemical, cement, mining and processing plants, which intensely receive raw materials by rail, have wagon unloading stations.

In case of open-top wagons usage for a bulk loads transportation by rail (for example, coal, iron ore raw stuff, limestone, sulfur transportations etc.), rotary or side wagon tipplers are used for unloading them. According to a load type and wagon design type the lifting capacity of an open-top wagon can be from 60 to 134 ton.

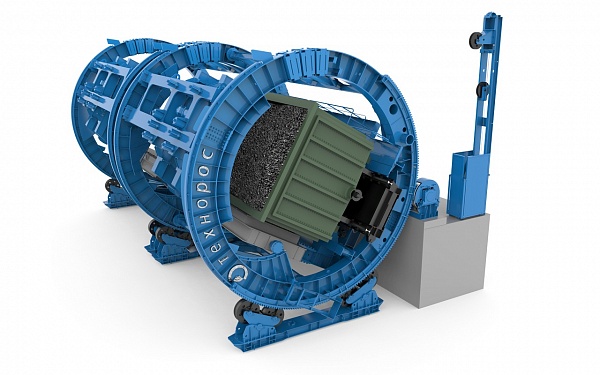

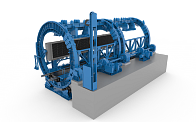

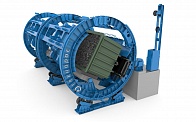

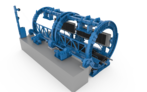

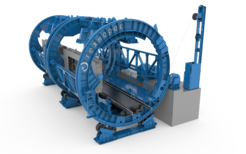

The rotary type wagon tippler of VRS-93-110 is traditionally used for unloading an open type wagons, which contain bulk cargoes of net weight loading capacity up to 110 t. This type of rail wagon tippler is mostly common at Russian and CIS state enterprises.

After a number of made modernizations and design improvements VRS-93 type is still effective technological equipment: reliable and durable.

Such a rail wagon tippler type has 4 pillars, which reduces a load on metal structures and building part of a wagon unloading station.

The loading capacity of VRS-93 type rotary wagon tippler – up to 110 ton. The equipment production capacity – up to 1500 ton per hour.

- High production capacity (up to 25 wagons per hour);

- Low energy consuming;

- Easy in service.

The application of VRS-93 type is the most effective for existing wagon unloading stations reconstruction. In this case, a new rotary wagon tippler can be settled at the same building foundation pillars, which significantly lowers capital expenditures of the project.

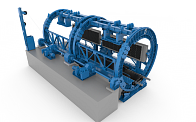

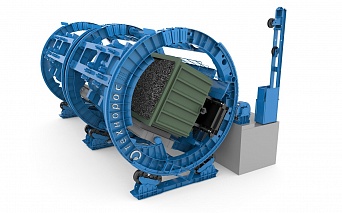

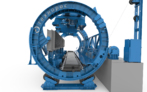

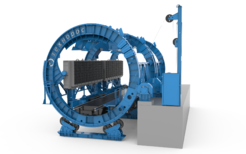

The optimal solution for equipping of a new wagon unloading station is VRDS-100 rotary wagon tippler.

This type of wagon tippler has 2 pillars. It defines a possibility to for most free arrangement of a station.

Lack of top beam and middle pillars in wagon tippler’s design provides the most easy emptying of cargo and eliminates back cast of the unloaded material.

________________________________________________________________________________________________________________________________________________________

- Reliable open-top wagon fixing on a unloading platform.

- Automated central lubrication system.

The loading capacity of VRDS-100 type rotary wagon tippler – up to 110 ton. The equipment production capacity – up to 1250 ton per hour.

For 120 ton and 134 ton weight rail open-top wagon unloading VRS-120 and VRS-134 rotary wagon tippler types are used.

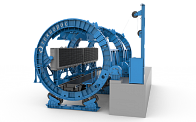

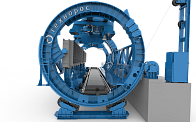

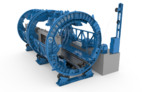

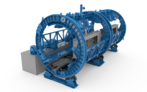

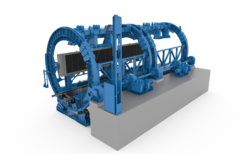

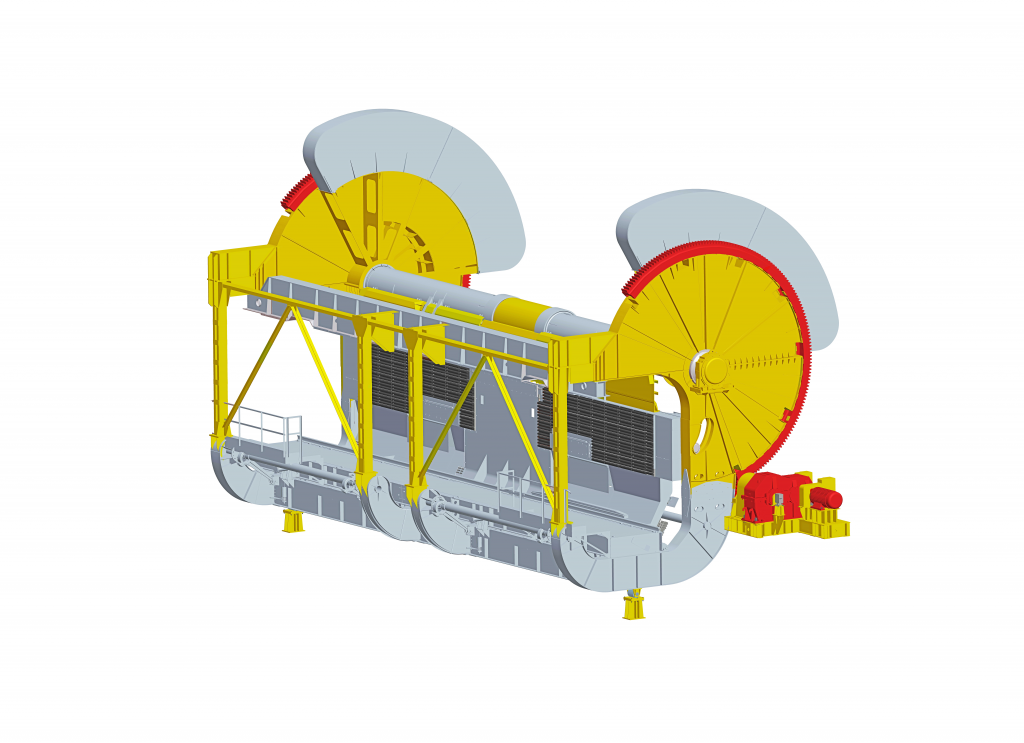

For unloading of two open-top bulk cargo wagons at a time the tandem rotary wagon tippler type VRDS-200 is used. The material is being unloaded to an underground receiving hopper.

Tandem (doubled) wagon tipplers are used, when a high intensity of a railway rolling stock unloading is necessary. For example, at specialized marine terminals. Usually, such wagon tipplers are used with wagon positioners and therefore rotors have the C-shaped form.

_________________________________________________________________________________________________________________________________________________________

- High automating level of the unloading process due to positioner using.

- The possibility to unload large-lump and partially frozen loads, due to full opened wagon tippler’s top.

The loading capacity of VRDS-200 type rotary wagon tippler – up to 200 ton. The equipment production capacity – up to 2500 ton per hour.

_________________________________________________________________________________________________________________________________________________________

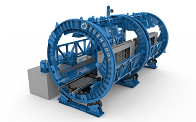

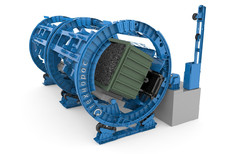

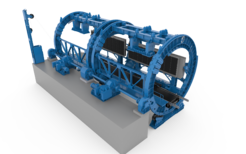

- Suitable for areas with rock grounds or high underground waters level, as well as with other difficulties, concerning a wagon unloading station arrangement to a depth of 18 meters.

- Lowers capital construction costs, due to building foundation deepening reduce.

Depending on a construction design and a cargo type being transported, the lifting capacity of VBS type wagon tippler can be from 60 to 134 ton. The equipment production capacity – up to 1860 ton per hour.

It would be a pleasure for us to offer the most efficient solution to your business. Just call us +7 (981) 713-57-08.

Our specialists will answer all your questions and give you detailed information about our equipment. You can write us to info@tehnoros.ru, as well.

In case of open-top wagons usage for a bulk loads transportation by rail (for example, coal, iron ore raw stuff, limestone, sulfur transportations etc.), rotary or side wagon tipplers are used for unloading them. According to a load type and wagon design type the lifting capacity of an open-top wagon can be from 60 to 134 ton.

The rotary type wagon tippler of VRS-93-110 is traditionally used for unloading an open type wagons, which contain bulk cargoes of net weight loading capacity up to 110 t. This type of rail wagon tippler is mostly common at Russian and CIS state enterprises.

After a number of made modernizations and design improvements VRS-93 type is still effective technological equipment: reliable and durable.

Such a rail wagon tippler type has 4 pillars, which reduces a load on metal structures and building part of a wagon unloading station.

The loading capacity of VRS-93 type rotary wagon tippler – up to 110 ton. The equipment production capacity – up to 1500 ton per hour.

VRS-93 type wagon tippler benefits are:

- The ability to unload the majority of modern types of open-top wagons;- High production capacity (up to 25 wagons per hour);

- Low energy consuming;

- Easy in service.

The application of VRS-93 type is the most effective for existing wagon unloading stations reconstruction. In this case, a new rotary wagon tippler can be settled at the same building foundation pillars, which significantly lowers capital expenditures of the project.

The optimal solution for equipping of a new wagon unloading station is VRDS-100 rotary wagon tippler.

This type of wagon tippler has 2 pillars. It defines a possibility to for most free arrangement of a station.

Lack of top beam and middle pillars in wagon tippler’s design provides the most easy emptying of cargo and eliminates back cast of the unloaded material.

________________________________________________________________________________________________________________________________________________________

VRDS-100 type wagon tippler benefits are:

- The possibility to unload large-lump and partially frozen loads.- Reliable open-top wagon fixing on a unloading platform.

- Automated central lubrication system.

The loading capacity of VRDS-100 type rotary wagon tippler – up to 110 ton. The equipment production capacity – up to 1250 ton per hour.

For 120 ton and 134 ton weight rail open-top wagon unloading VRS-120 and VRS-134 rotary wagon tippler types are used.

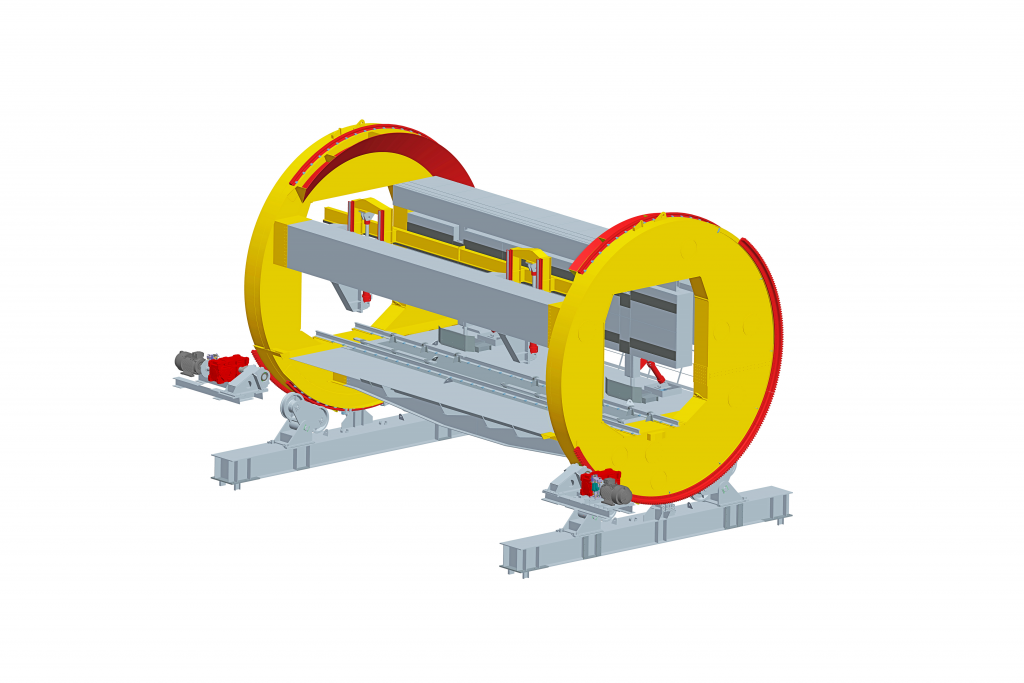

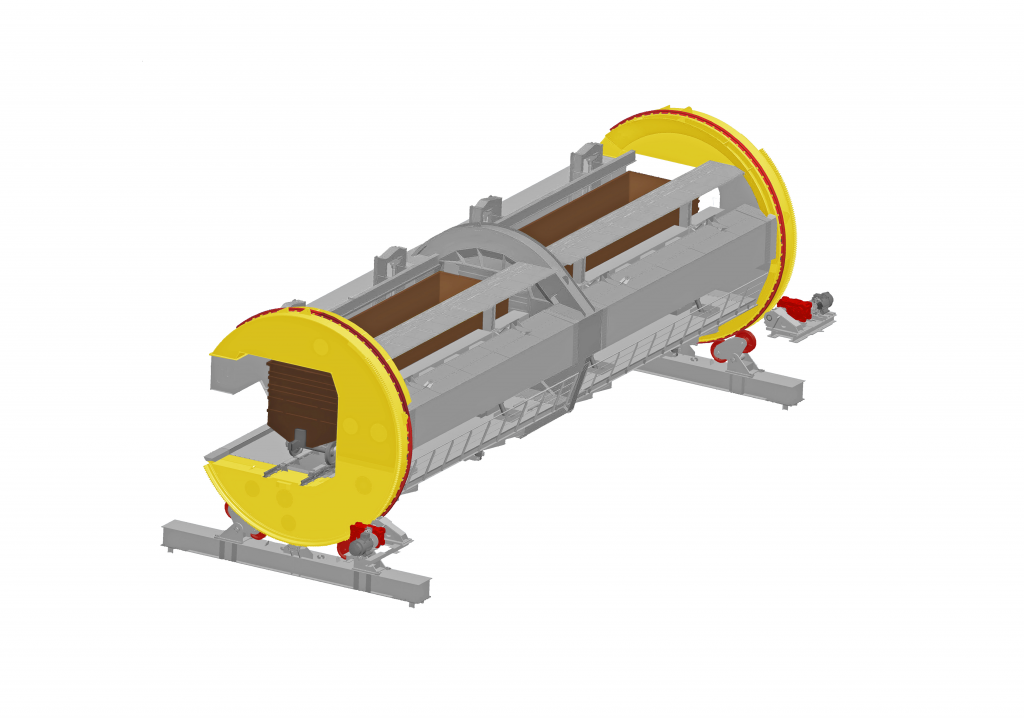

For unloading of two open-top bulk cargo wagons at a time the tandem rotary wagon tippler type VRDS-200 is used. The material is being unloaded to an underground receiving hopper.

Tandem (doubled) wagon tipplers are used, when a high intensity of a railway rolling stock unloading is necessary. For example, at specialized marine terminals. Usually, such wagon tipplers are used with wagon positioners and therefore rotors have the C-shaped form.

_________________________________________________________________________________________________________________________________________________________

VRDS-200 type tandem (doubled) wagon tippler benefits are:

- High production capacity of the system, due to simultaneous unloading of two open-top wagons.- High automating level of the unloading process due to positioner using.

- The possibility to unload large-lump and partially frozen loads, due to full opened wagon tippler’s top.

The loading capacity of VRDS-200 type rotary wagon tippler – up to 200 ton. The equipment production capacity – up to 2500 ton per hour.

_________________________________________________________________________________________________________________________________________________________

VBS type wagon tippler benefits are:

- Helps to deepen auxiliary equipment to significantly less depth.- Suitable for areas with rock grounds or high underground waters level, as well as with other difficulties, concerning a wagon unloading station arrangement to a depth of 18 meters.

- Lowers capital construction costs, due to building foundation deepening reduce.

Depending on a construction design and a cargo type being transported, the lifting capacity of VBS type wagon tippler can be from 60 to 134 ton. The equipment production capacity – up to 1860 ton per hour.

It would be a pleasure for us to offer the most efficient solution to your business. Just call us +7 (981) 713-57-08.

Our specialists will answer all your questions and give you detailed information about our equipment. You can write us to info@tehnoros.ru, as well.

Back to the list